A large volume filter plant by Edward & Jones

Mechanised Presses can be supplied in both sidebar and overhead form and incorporate features such as:

- Double acting hydraulic opening and closing

- Hydraulically operated hinged drainage trays

- Plate movement system

- Photo electric light guards

- Cloth washing

Mechanical Plate Movement

Mechanisation of the filter press invariably includes our plate movement system which is infinitely variable for use on our sidebar or overhead design and also fully adjustable to accommodate polypropylene or cast iron plates. A unique feature of our system is the hold back facility so that only one plate at a time is transferred with a positive stacking when deposited.

Mechanised sidebar press featuring plate movement system (featured below), double acting electro hydraulic opening/closing, hydraulically operated hinged drainage trays and photo electric light guards.

We Supply:

-

Plate filter presses

-

Horizontal Belt filter presses

-

Inclined & Horizontal Screw presses

-

Filter cloth and paper

-

Filter plates

Plate filters

These are available in different sizes from 250 mm to 2000 mm. They can be flush and frame, recessed, and membrane type. Can be centre feed or corner feed. Small press can be manually operated and larger ones are mechanised and can be semi-automated as well. There are plate mover , cloth wash options also available.

Belt filter

The POLYFITER Horizontal process filter is probably the most versatile filter in the market place today. If your product, or effluent sludge, can be filtered in the laboratory on a Buchner filter, it can be filtered on a POLYFILTER Horizontal process filter .

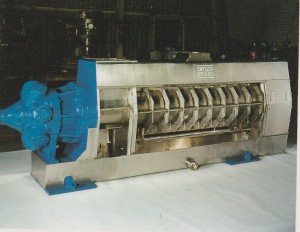

Inclined & Horizontal screw Press

Horizontal and inclined Screw presses, for de-watering of fibrous products and separating of fluids from solids. Used in paper making, food processing, brewing and distilling. Also used in effluent plants and water reclamation.

INCLINED Screw Press

Horizontal Screw Press

Filter cloth & Paper

Most filtration techniques require the use of filter media; the media is the heart of the filter. It is important to choose a suitable material of construction and to specify correctly the filter media. Filter cloth is supplied natural and synthetic fabrics in a variety of weights and weaves to satisfy a wide range of filtration requirements .Filter paper can be supplied in a selection of sizes and qualities to meet the needs of applications where cloth blinding is a problem and where high degree of separation is required.

Filter plates

LENSER plates are the leading manufacturer of thermoplastic filter elements (mainly Polypropylene) for the industry used in filter press. With plate dimensions up to 2450 x 2450 mm, we are able to solve almost every challenge in solid/liquid separation.